Operation Weight

14500KG

Rated Power:

132 KW

Blade Width:

3658MM

The JM180H motor grader boasts user-friendly operation, featuring a single-handle electro-hydraulic power shift transmission with 6 forward and 3 reverse gears. It is equipped with a unique hydraulic lock and an auto lock/unlock NO-SPIN differential, enhancing stability and traction. Further, its optimized axle load allocation allows for efficient and reliable performance, even during tough cutting tasks on hard surfaces. This combination of features ensures the JM180H is both efficient and dependable in various conditions.

| Model | JM180H |

|---|---|

| Length×Width×Height(mm) | 8630×2600×3370 |

| Operating weight (Kg) | 14500 |

| Blade dimensions (mm) | 3658×545×16 |

| Traveling gears | 6 Forward 3 Reverse |

| Traveling speed forward(km/h) | 6.5/11.4/14.6/24.8/30/49.2 |

| Traveling speed reverse(km/h) | 6.5/14.6/30 |

| Diesel engine | Cummins 6BT5.9-C180 |

| Rated output(KW) | 132 |

Adopt Cummins turbocharged engine for high productivity with low fuel consumption. The durable mechanical inline fuel injection system offers precise throttle control, enhancing work speeds and horsepower.

Single-handle electro-hydraulic controlled power-shift transmission, with 6 forward and 3 reverse shifts, ensures easy and convenient operation. The ZF-technology powershift transmission perfectly complements the Cummins engine, providing reliability and ease of operation in various working conditions.

Box-type d frame and advanced T/M enable it to complete heavy-duty work

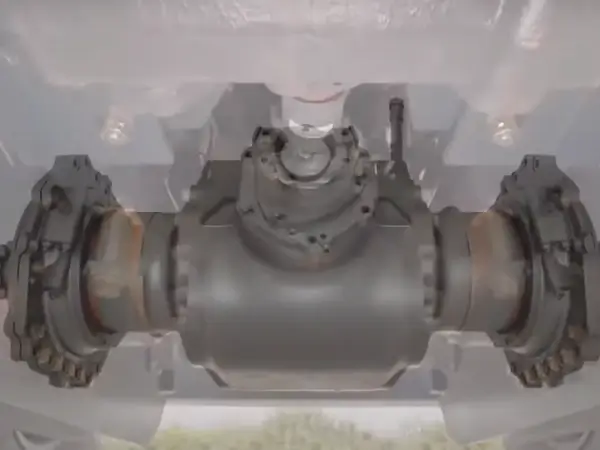

Features a hydraulic lock and an automatic lock/unlock NO-SPIN differential, ensuring stability and powerful traction.

A wide working range is accomplished through flexible blade suspension system and articulated frame

The drawbar use a robust A & U-shaped frame, designed for enhanced strength, durability, and precise control in blading operations.

A wide working range is accomplished through flexible blade suspension system and articulated frame

axle load allocation provides excellent stability, particularly when cutting hard surfaces.

Serviceable and efficient, ensuring maximum utilization of each component. A reliable full hydraulic brake system guarantees safety.

Superior visibility and a well-laid-out side pillar enhance the operator's confidence and productivity. The blade linkage is positioned for an unobstructed view of the moldboard and front tires.

Front Dozer Option: A front-mounted tool for spreading materials and blading in hard-to-reach areas.

For breaking up hard materials not removable by the moldboard. The V-type scarifier can hold up to 11 teeth, and the ripper up to 3-9 shanks.

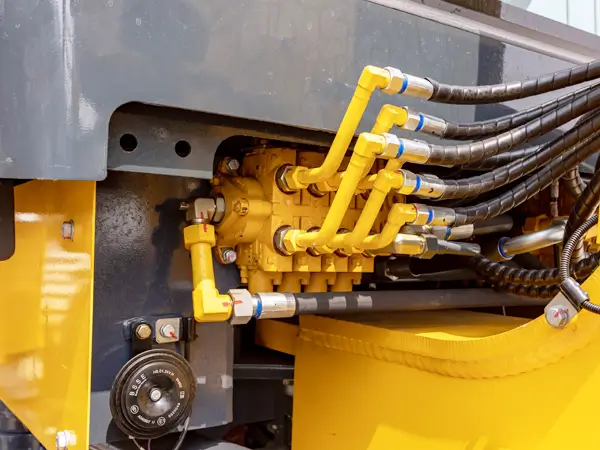

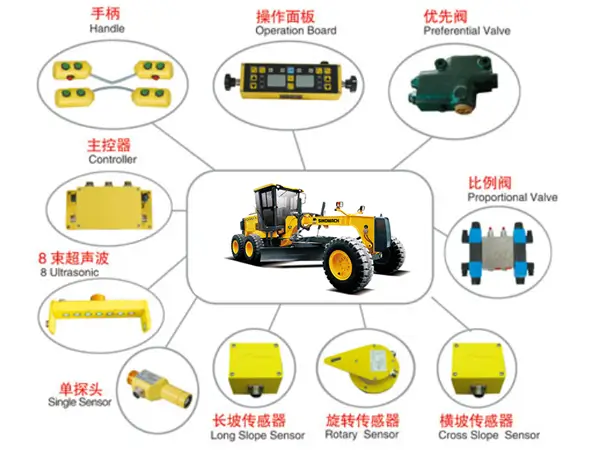

A 2D control system that offers precise height and slope control with flexibility in sensor choice and application fields.

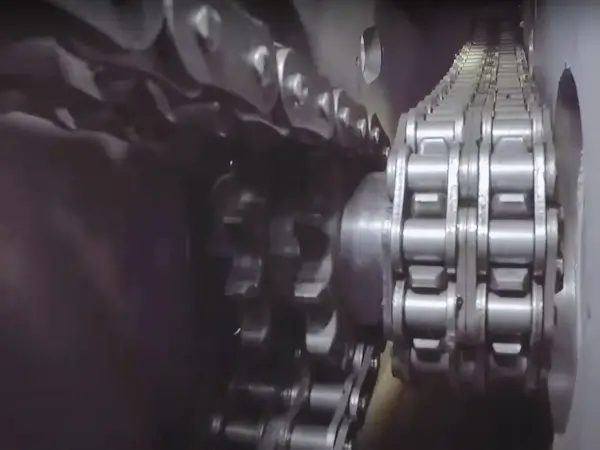

Ensures stronger transmission reliability.

Guarantees strength, with a tensile strength of 26 tons, surpassing industry and national standards.

We will contact you within 2 hours, please pay attention to the email with the suffix “@junma-group.com”.