Operation Weight

12000KG

Rated Power:

97 KW

Blade Width:

3658MM

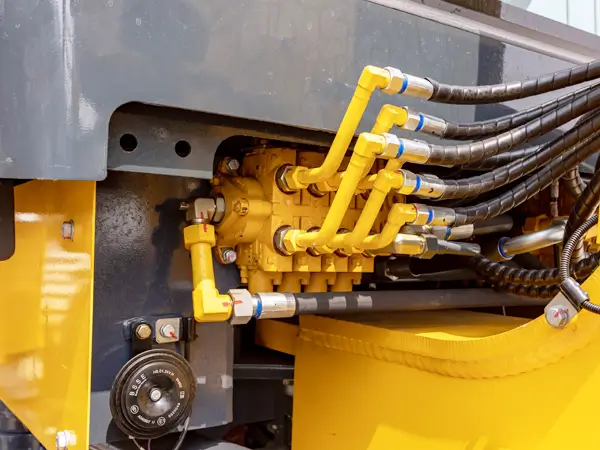

The JM150H motor grader adopts a user-friendly design with power shift transmission, electro-hydraulic control, and a single-handle operation system. It offers a smooth driving experience with 6 forward and 3 reverse gear options. The grader is equipped with a highly efficient hydraulic system that includes a hydraulic locking device, ensuring each unit operates reliably and stably. Additionally, it is designed with a comprehensive, fully hydraulic brake system, prioritizing high working safety in its operations.

| Basic specifications | |

|---|---|

| Engine model | Cummins 6BT5.9-C150 |

| Rated power | 120kW@2200rpm |

| Dimension (L×W×H) | 8290×2600×3465 (mm) |

| Operating weight (Standard) | 12000kg |

| Performance specifications | |

| Travelling speed, forward | 6.9/10.7/17.3/26/37.8/53.4 |

| Travelling speed, reverse | 6.9/17.3/37.8 |

| Tractive force (f=0.75) | 61.7KN |

| Operating specifications | |

| Max. steering angle of front wheels | 49° |

| Max. lean angle of front wheels | 17° |

| Max. oscillation angle of front axle | 16° |

| Max. oscillation angle of balance box | 13° |

| Frame articulation angle | 26° |

| Min. turning radius using articulation | 6.6m |

| Blade | |

| Maximum lift above ground | 410mm |

| Maximum grading depth | 560mm |

| Maximum blade position angle | 90° |

| Blade cutting angle | 29°~77° |

| Circle reversing rotation | 360° |

| Moldboard width × height | 3658×580mm |

Adopt Cummins turbocharged engine for high productivity with low fuel consumption. The durable mechanical inline fuel injection system offers precise throttle control, enhancing work speeds and horsepower.

Single-handle electro-hydraulic controlled power-shift transmission, with 6 forward and 3 reverse shifts, ensures easy and convenient operation. The ZF-technology powershift transmission perfectly complements the Cummins engine, providing reliability and ease of operation in various working conditions.

Box-type d frame and advanced T/M enable it to complete heavy-duty work

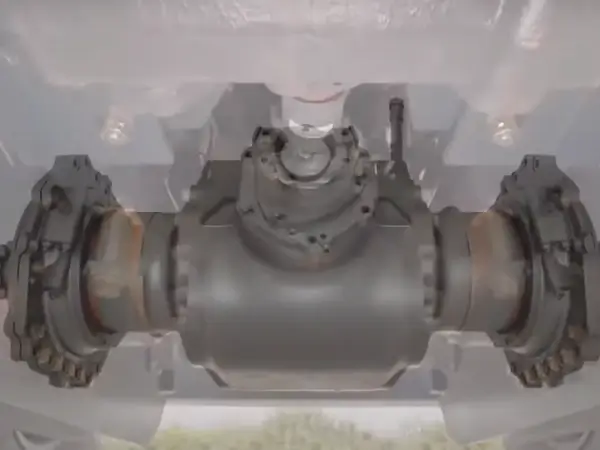

Features a hydraulic lock and an automatic lock/unlock NO-SPIN differential, ensuring stability and powerful traction.

A wide working range is accomplished through flexible blade suspension system and articulated frame

The drawbar use a robust A & U-shaped frame, designed for enhanced strength, durability, and precise control in blading operations.

A wide working range is accomplished through flexible blade suspension system and articulated frame

axle load allocation provides excellent stability, particularly when cutting hard surfaces.

Serviceable and efficient, ensuring maximum utilization of each component. A reliable full hydraulic brake system guarantees safety.

Superior visibility and a well-laid-out side pillar enhance the operator's confidence and productivity. The blade linkage is positioned for an unobstructed view of the moldboard and front tires.

Front Dozer Option: A front-mounted tool for spreading materials and blading in hard-to-reach areas.

For breaking up hard materials not removable by the moldboard. The V-type scarifier can hold up to 11 teeth, and the ripper up to 3-9 shanks.

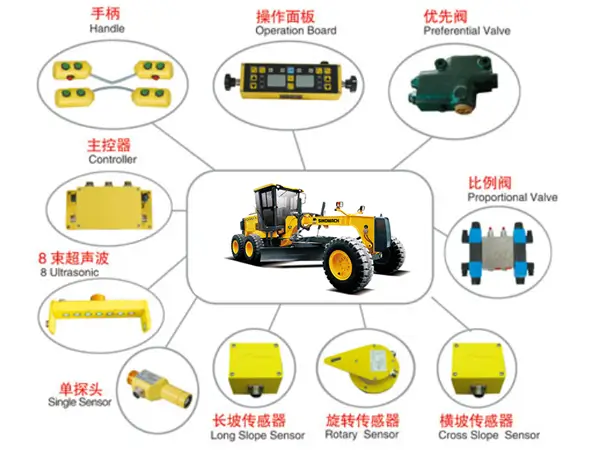

A 2D control system that offers precise height and slope control with flexibility in sensor choice and application fields.

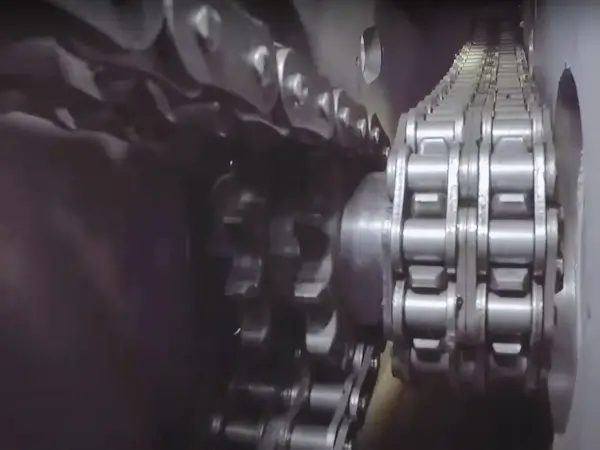

Ensures stronger transmission reliability.

Guarantees strength, with a tensile strength of 26 tons, surpassing industry and national standards.

We will contact you within 2 hours, please pay attention to the email with the suffix “@junma-group.com”.